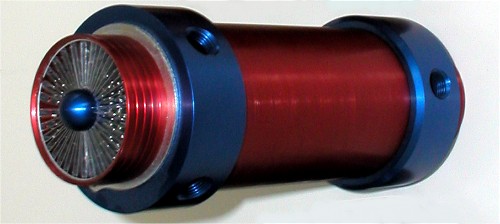

The Thermal Hard Pipe is an air to water intercooler made from Aluminum. Aluminum is known for the fact that is has a very fast heat transfer rate compared to other metals. When we pass heated air through the inner finned tube "Air Passage", the heated air passes over these fins and they absorb the heat. From there, we pull that heat out and away from those fins by the outer jacket's Coolant Passage.

Hier een kitje compleet THP KIT WITH w/O-RING CAPS

Code: THP-KIT-ORING

Price: $639.00

Euro 464,-

INTERCOOLER TUBES

Designed and manufactured exclusively by Lindsey Racing, these "Thermal Hard Pipes" may be the answer you have been looking for.

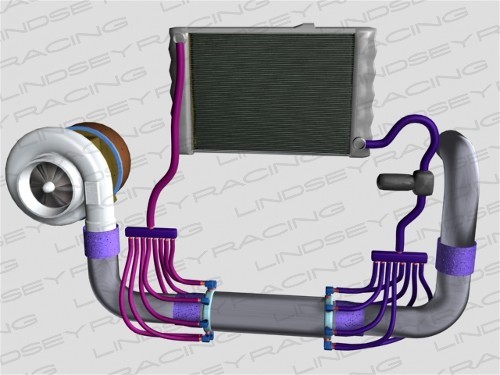

The intended use is for cooling the intake charge air in turbocharged and supercharged applications. When you have plumbing from the compressor to the intake, these can replace that standard tubing plumbing and be used to cool the charge air at the same time.

You can use as a supplemental cooling solution in conjunction with an existing standard intercooler or as the sole primary cooling method.

This universal product allows you, the end user, to determine where and how you will implement it into your application. We can provide the Thermal Hard Pipe, fittings, pumps and hose, and you take it from there to dream up and apply the solution.

Lindsey Racing's "Thermal Hard Pipes" are made from 6061 aluminum. This latest design is a modular piece that we assemble at time of order. Our 12" cooler has a total of 18 separate components in it's assembly. This allows us flexibility in not only color combinations, but enables us to incorporate different fin designs for specific applications in the future.

The most visible change in this latest design is the new fin arrangement. There are 58 cooling fins in a radial pattern that are .008" thick. The thin fins allows for a quick transfer of heat. Each linear inch of the cooler has 101.5 square inches of heat transfer surface compared to our previous extruded design which had 37. The fins are over 12 times thinner for quicker heat transfer as well.

The claim of 101.5" is actually only temporary during the manufacturing process. Those same fins are perforated or punched with small holes over the entire fin surface which eliminates 15% of the original surface.

The most effective part of any cooling fin is the leading edge. It's referred to as the Frontal Boundry Area. By perforating the fins with holes, we have leading edges throughout the entire cooler giving us Frontal Boundary Area from the front of the cooler to the rear as the air passes across the effective half circles leading edges.

In addition to that, the fins are formed with a wave or curve back and forth to them called Ruffled. You cannot see through our coolers because of this. There are design considerations in this Ruffle called Pitch and Amplitude. If you think of it as waves in the ocean, the Pitch would be the distance between the waves and the Amplitude is the height of the waves. This is used to force the air to stay in more continual contact with the fin surface versus just sliding or slipping past it. While the air passes through the cooler, the air shifts from one side to the other and is allowed to move from one row to the other through the perforations finding the path of least resistance while contacting the Frontal Boundary Area.

If this all sounds strange to you, consider this. The company that produces our fins claims this design is the only fin that was found to adequately cool the oil in the US Navy's V-22 Osprey Tilt-Rotor aircraft. Since they produce this same similar design for us as they do the Osprey, we can say with confidence our fin design is pretty high tech!